Struggling with concrete placement in tight spaces, remote sites, or across multiple projects? Traditional methods often mean high costs, logistical headaches, and frustrating delays. You need a solution that combines power with unparalleled flexibility.

The trailer mounted concrete pump is the answer. This highly mobile equipment transforms how you place concrete, offering the ultimate in job-site adaptability. It delivers a powerful, steady flow of concrete exactly where and when you need it, turning challenging locations into manageable tasks.

| Models | HBTS/JBS Series |

| Concrete Output Capacity | 30 ~ 90 m³/h |

| Pumping Pressure | 6 ~ 20 MPa |

| Engine Power | Diesel / Electric 52 ~ 199kW |

| Max. Transportation (V/H) | 300m/1200m |

| Distribution Type | S valve |

What Is A Trailer Mounted Concrete Pump

At its core, a trailer mounted concrete pump is a high-output concrete pumping system permanently mounted on a towable trailer chassis. This straightforward yet powerful design is its greatest strength, creating a fully self-contained unit that can be hitched to a truck or tractor and transported to virtually any job site.

This setup is fundamentally different from its counterparts. Unlike stationary pumps, the trailer pump is defined by its mobility. And unlike truck-mounted boom pumps, a towable concrete pump is a separate, versatile asset. This means your hauling vehicle is free once the pump is in position, eliminating the cost of tying up an expensive truck for the entire duration of the pour.

Top 5 Advantages of a Trailer Mounted Concrete Pump

Investing in equipment is about boosting your business’s bottom line. The advantages of a trailer mounted concrete pump translate directly into tangible benefits that save you time, reduce costs, and unlock new revenue opportunities.

Unbeatable Mobility & Flexibility

The core of its design is mobility. This flexibility allows your crew to complete a foundation pour in the morning and a slab pour across town in the afternoon, maximizing the utility of a single asset.

Lower Acquisition & Operational Costs

When compared to a large truck-mounted boom pump, a trailer-mounted model is the clear cost saving concrete pump solution. The initial investment is significantly lower, and it doesn’t require a dedicated, expensive truck to operate.

Access to Confined and Remote Sites

A trailer pump’s compact size and maneuverability allow it to navigate tight urban alleyways, forested paths, or rough rural terrain where large trucks cannot go. This capability opens up a new market of projects for your business.

Quick Setup and Easy Operation

Time is money on any job site. These pumps are designed for rapid deployment. Once on location, they can be leveled and ready to pump in minutes, minimizing labor costs and ensuring your projects stay on schedule.

Reliable Performance for a Wide Range of Projects

Modern trailer mounted concrete pumps are engineered for power and endurance, capable of handling high-volume residential builds, sturdy industrial floors, and intricate agricultural projects.

How to Choose the Right Trailer Mounted Pump

Selecting the right equipment is critical to your project’s success and profitability. Knowing how to choose a trailer mounted concrete pump requires a clear understanding of key trailer pump specifications.

Output Volume (m³/h) – Matching Pump Capacity to Your Projects

The trailer mounted concrete pump output capacity determines how quickly you can place concrete. Analyze your typical project sizes and choose a pump with an output volume that meets your peak demands without excess.

Max Pressure & Reach – Understanding Vertical and Horizontal Distance

Concrete pump pressure directly dictates the pump’s reach—both vertically and horizontally. Higher pressure is essential for pumping to the upper floors of multi-story buildings or across vast industrial sites.

Engine Power & Fuel Efficiency

Sufficient power is non-negotiable for maintaining consistent output. Modern trailer mounted concrete pumps strike a balance with advanced, fuel-efficient engines that deliver reliable performance without excessive running costs.

Chassis Durability & Ease of Maintenance

A robust chassis made of high-strength steel can withstand the stresses of transportation. Look for features like easy-access panels to key components to significantly reduce service time and minimize unplanned downtime.

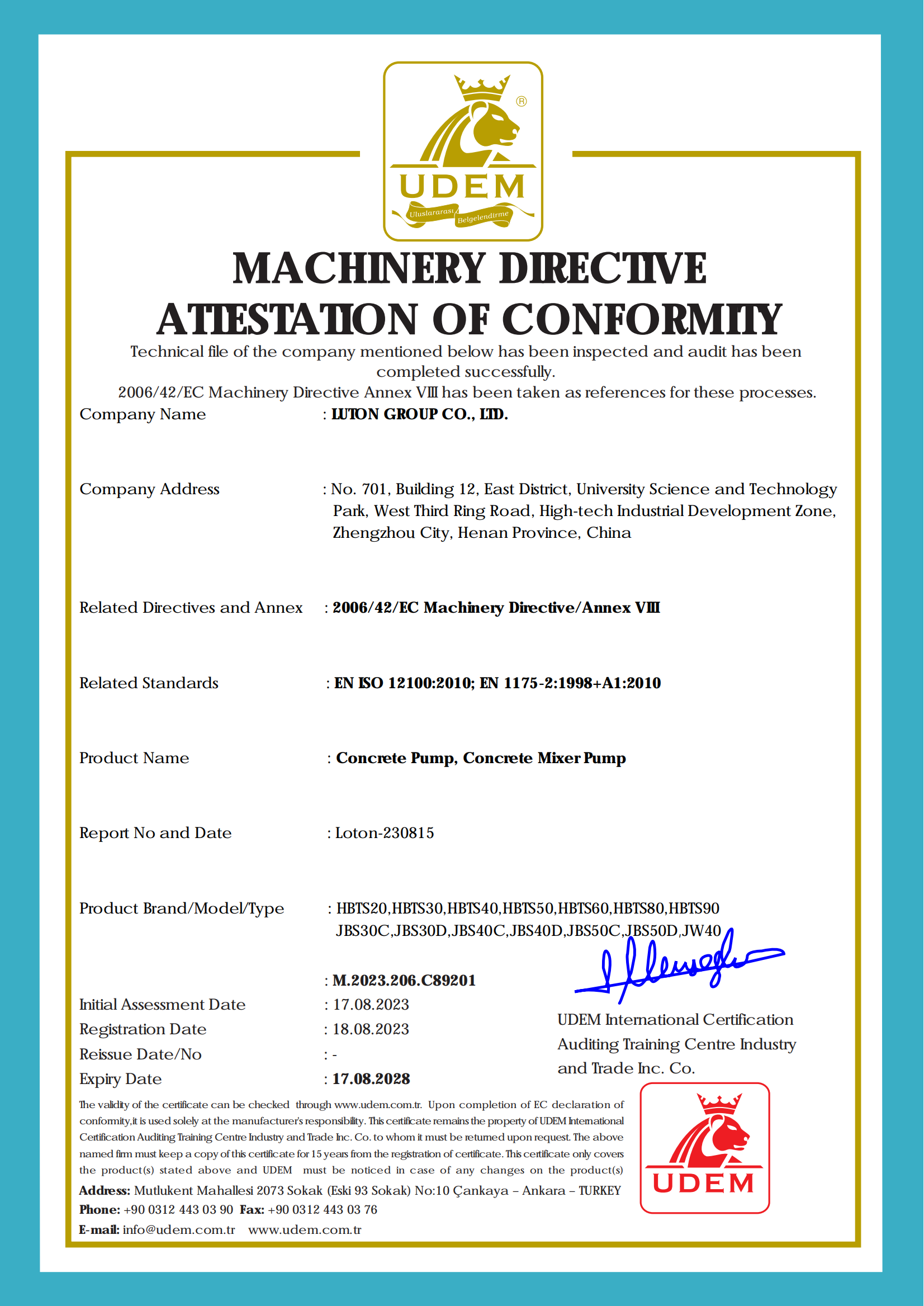

LUTON Trailer Mounted Concrete Pumps – Engineered for Reliability & Performance

Now that your understand the “why” and “what”, it’s time to discover the “who”. While any trailer mounted concrete pump can offer mobility, only a select few are built to withstand the relentless demands of professional contracting. At LUTON, we don’t just manufacture equipment. We engineer peace of mind. As a reliable concrete pump manufacturer, we build durability, innovation, and support into every machine, ensuring your business keeps moving forward, pour after pour.

Our Product Line-up – A Model for Every Application

We recognize that no two projects are identical. That’s why we offer a curated range of trailer pumps designed to meet specific challenges. Our flexible series includes:

Economical

Perfect for smaller contractors and residential projects, delivering exceptional value and essential performance.

Professional

Our best-selling range, engineered for versatility and durability in demanding daily use across commercial and industrial sites.

Advanced

For the challenging applications, offering top-tier output, pressure and advanced features for high-requirement projects.

This strategic lineup ensures that you never have to overpay for capacity you don’t need or compromise on power for the jobs you want to win.

Spotlight on LUTON – An In-depth Look

Meet the powerhouse that sets the industry standard: the LUTON HBT-series products. These models embody our commitment to performance and are the ultimate expression of what a LUTON trailer pump can achieve.

Key Specifications & Features

Powerful & Efficient: Equipped with a Weichai turbocharged engine, delivering robust performance with best-in-class fuel efficiency.

Intelligent Control System

A user-friendly, CAN-BUS based interface provides real-time monitoring of all critical functions, automatic fault diagnosis, and smooth, precise control for optimal concrete flow.

Unmatched Durability

Features hardened alloy steel delivery cylinders and a S-tube valve system, proven to extend component life by up to 40% under abrasive conditions. Constructed from high-tensile steel with reinforced outriggers for unwavering stability during operation, even on uneven ground.

Easy Maintenance

A centralized lubrication system and strategically placed service doors drastically reduce daily maintenance time and minimize unscheduled downtime.

Why LUTON Stands Out – The Contractor’s Choice

Choosing a pump is about more than specs. It’s about choosing a partner. Here’s why contractors globally trust us:

Quality Without Compromise

We implement rigorous quality control at every stage, from material selection to final assembly, ensuring every pump meets our stringent global standards.

Industry-leading Warranty & Support

We back our quality with a comprehensive one-year warranty and a 24/7 global support network. Our team is always ready to help you keep your project on track.

Custom Solutions

Have a unique requirement? Our engineering team specializes in developing tailored solutions, from special trailer configurations to specific pressure and output needs.

When you invest in a LUTON pump, you are investing in more than a machine – you are investing in a tool build your future.

Case Studies – LUTON Pumps In Action

Seeing is believing. The true value of our equipment is demonstrated not in specifications, but in real-world performance under demanding conditions. These LUTON cases study examples showcase how our trailer mounted concrete pumps have become indispensable partners for contractors worldwide, turning complex challenges into resounding successes.

Case Study 1: Accelerating a Rural Housing Estate In Kenya

The Challenge

A developer faced tight deadlines and difficult site access in a remote, hilly area. Large pump trucks were logistically impossible and financially prohibitive. They needed a solution that could navigate narrow, unpaved roads and place concrete efficiently for multiple house foundations.

The Solution

The contractor deployed our JBS40. Its compact, towable design allowed easy transport to the site, and its powerful output pressure effortlessly handled the inclines and long pipeline runs required.

The Result

The project completed the concrete pouring phase 30% faster than scheduled. The contractor highlighted the pump’s “unmatched mobility and reliability” as key to overcoming logistical nightmares, ensuring the housing project stayed on budget and timeline.

Case Study 2: Building a Modern Agricultural Facility with Limited Access

The Challenge

Constructing a large-scale oil chemical factory required concrete placement in multiple confined areas in Indonesia.

The Solution

Our versatile trailer pump for agricultural construction provided the prefect answer. Its ability to be positioned precisely and pump both horizontally and vertically allowed the crew to reach every corner of the complex site without compromise.

The Result

The contractor completed all concrete work with precision and speed, avoiding costly manual labor or alternative methods. This demonstrated that a LUTON trailer pump is not just for standard builds but is a critical tool for specialized projects.

These cases are just a glimpse of how we help our customers succeed. Let your next project be our next success story.

Frequently Asked Questions (FAQ)

You have questions, and we have clear answers. This trailer mounted pump FAQ is designed to address your most common concerns, helping you feel confident in choosing LUTON as your trusted partner.

Q: How many operators are needed to run the pump?

A: Typically, only one to two trained operators are required. Our trailor mounted concrete pumps are designed with intuitive controls for ease of operation, allowing for efficient crew management. For detailed guidance, please refer to our manual on how to operate a trailer concrete pump safely and effectively.

Q: What warranty and support do you offer?

A: We stand firmly behind the quality of our products. Every LUTON pump is backed by a comprehensive one-year warranty on major components. Furthermore, our global support network provides 24/7 technical assistance and ensures rapid availability of genuine spare parts to minimize your downtime.

Q: Do you provide operator training?

A: Absolutely. We offer comprehensive operator training for all our clients. This can be conducted at your facility or via detailed instructional sessions, ensuring your team is fully equipped to maximize the pump’s performance and lifespan from day one.

The trailer mounted concrete pump stands as a testament to efficiency, combining unmatched mobility with powerful performance to conquer the toughest job sites. It is the strategic solution for contractors seeding to reduce costs, expand their project capabilities, and boost profitability.

You now have the knowledge to make an informed decision. The final step is to run this insight into action for your business.